You need to choose options for product.

-

files/A1-AMS.jpg

files/A1-AMS.jpg

-

files/A1-2_1600x1600_03a55a80-78f6-481e-bddb-a168629aed06.jpg

files/A1-2_1600x1600_03a55a80-78f6-481e-bddb-a168629aed06.jpg

-

files/A1_2_800x_6541499c-1ee5-4b1d-8e4c-3395d692d628.jpg

files/A1_2_800x_6541499c-1ee5-4b1d-8e4c-3395d692d628.jpg

- Regular price

- $629.00

Couldn't load pickup availability

Customers also bought

Product Description

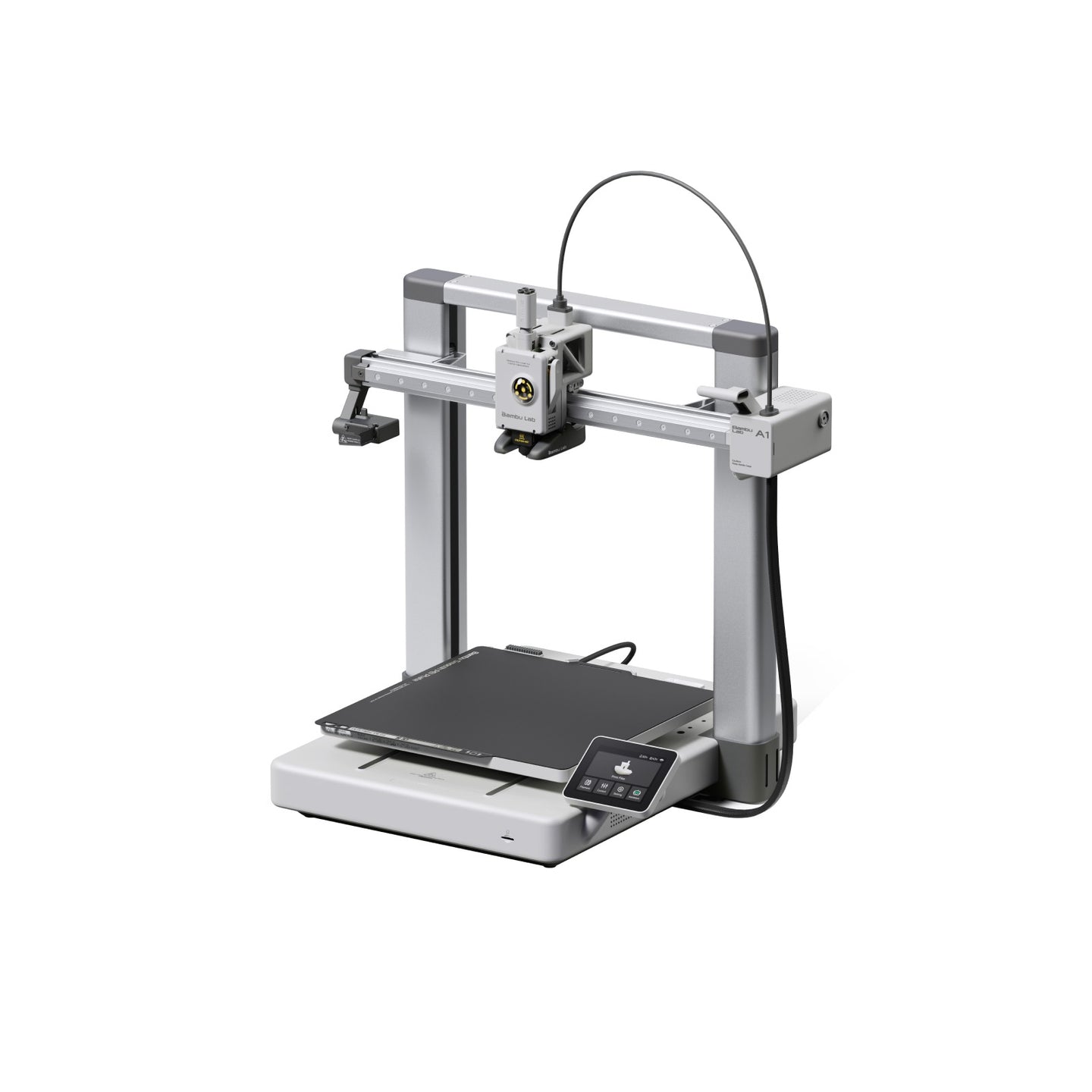

Bambu Lab A1 3D Printer

Product Features

- Full-auto Calibration

- Multi-Color Printing

- Active Flow Rate Compensation

- 1-Clip Quick Swap Nozzle

- Active Motor Noise Cancelling

- 256*256*256 mm³ Build Volume

Bambu Lab A1 Combo

- Multi-Color Printing

- Full-auto Calibration

- Active Flow Rate Compensation

- 1-Clip Quick Swap Nozzle

- Active Motor Noise Cancelling

- 256*256*256 mm³ Build Volume

Multi-Color Printing

The all-new AMS lite is elegant and reliable, making multi-color 3D printing accessible to everyone.

Active Flow Rate Compensation

The A1 revolutionizes flow control in 3D printing. It utilizes a high-resolution, high-frequency eddy current sensor to measure the pressure in the nozzle. Our algorithm actively compensates the flow rate according to the readings to extrude with accuracy.

Full Auto Calibration

The A1 handles various calibrations all by itself. It meticulously calibrates the Z-offset, bed-level, vibration resonance and nozzle pressure for EVERY print job, automatically.

Quick Swap Nozzle

All-new quick swap hotend design, the hotend pops in and out with just 1-Clip.

Active Motor Noise Cancelling

The A1 can calibrate parameters to match tiny individual differences between each drive motor. This compensates for the unwanted harshness of motor noise.

Bed Slinger, with CoreXY Speed And Quality

Full-metal rails, rigid frame, nozzle pressure sensor, accelerometers, powerful MCU, and above all, an advanced motion control system that utilizes these features to print a 14-minute benchy with quality and following all the speed benchy rules straight out of the box without using specialized filaments.

Sync with Bambu Studio and Bambu Handy

Remote control and monitor your printer on Bambu Studio or Bambu Handy. Through the built-in camera, you can also record timelapse videos.

A1 Tech Specs

| Item | A1 Specification | |

| Body | Build Volume(W*D*H) | 256*256*256 mm³ |

| Toolhead | Hot End | All-Metal |

| Nozzle | Stainless Steel | |

| Max Hot End Temperature | 300 °C | |

| Nozzle Diameter | 0.4 mm (Included) 0.2 mm, 0.6 mm, 0.8 mm |

|

| Heatbed | Build Plate | Bambu Textured PEI Plate (Included) Bambu High Temperature Plate (Smooth PEI) Bambu Cool Plate |

| Max Build Plate Temperature | 100°C | |

| Speed | Max Speed of Tool Head | 500mm/s |

| Max Acceleration of Tool Head | 10m/s² | |

| Supported Filament | PLA, PETG, TPU, PVA | Ideal |

| ABS, ASA, PC, PA, PET, Carbon/Glass Fiber Reinforced Polymer |

Not Recommended | |

| Sensors | Chamber Monitoring Camera | Low Frame Rate Camera (Up to 1080P) Timelapse Supported |

| Filament Run Out Sensor | Yes | |

| Filament Odometry | Yes | |

| Power Loss Recover | Yes | |

| Filament Tangle Sensor | Yes | |

| Physical Dimensions | A1 : 385*410*430 mm³ , Package size : 552*532*320 mm³ , Net weight 8.3 kg , Gross weight 11.7 kg A1 Combo : Package size 546*536*420 mm³ , Gross weight (AMS lite included) 14.3 kg |

|

Full advanced features of A1 3D printers : Learn more

What's in the box

Bambu Lab A1

Spool Holder

Purge Wiper

Build Plate

PTFE Tube*1

Bambu Filament Samples (Random Color)

Stainless Steel Nozzle(pre-installed)

Accessory Box

A1 Combo Add-ons

AMS lite Stand

AMS lite Body

AMS lite Rotary Spool Holder (x4)

PTFE Tube

Frequently asked questions

1. What is the maximum print size of the A1?

A: 256 * 256 *256 mm³. For more details, please check here.

2. What Filaments can A1 Print?

A: 1. Low-temperature filaments such as PLA, PETG, TPU, and support materials for PLA and PETG (Support for PLA, PVA, HIPS, etc.).

2. Conventional high-temperature filaments such as ABS, ASA, PC, PA, PA-CF/GF, PET-CF/GF, PPA-CF/GF, etc.

Kind Reminder:

The standard nozzle is made of stainless steel. When printing filaments containing hard particles (CF, GF, etc.) such as PLA-CF/GF, PLA Glow-in-the-dark, PETG-CF/GF and PAHT-CF/GF, it is necessary to replace the nozzle with hardened steel to prevent excessive wear.

Due to the A1's open-frame design and lower chamber temperature, there is a risk of reduced interlayer strength and increased warping for large-sized models and models with high filling density when using conventional high-temperature filaments such as ABS, ASA, PC, PA, PA-CF/GF, PET-CF/GF, PPA-CF/GF, etc. on the A1. However, these high-temperature filaments can be used on the A1 to print small-sized models with low filling density. The printing results may vary depending on the filaments' dry and wet state, the characteristics of the model itself, printing parameters, and the ambient temperature. For more details, please check here.

3. Is it OK to enclose the A1?

A: We don't recommend enclosing the A1. For more details, please check here.

4. Can you use multiple AMS lite units with the A1 for up to 16 color prints?

A: The A1 can only support one AMS lite, which means it can print with a maximum of 4 colors. For more details, please check here.

5. Can I use the AMS on the A1?

A: No, AMS is incompatible with the A1. You must use the AMS lite if you want a multi-color print using A1. For more details, please check here.

6. Can AMS lite be mounted on the beam of the A1 to reduce space occupation? If so,how should I proceed with the operation?

A: Please visit our MakerWorld model website, where you will be able to find the model supports, installation tutorial, and purchase links for accessory screws. Additionally, you can also refer to our wiki page for more related information.

For more details, please check here.

7. If I install AMS lite on the beam, will the filament spool slide down, or will it affect the accuracy of vibration compensation?

A: As long as the AMS lite is correctly installed, the filament spool should not slide down, even if the previous two spools have a certain forward tilt angle. Additionally, to avoid affecting the accuracy of vibration compensation, you can add reinforcement to the column. For more details, please check here.